Precision Modular & Tension Polyurethane Screens

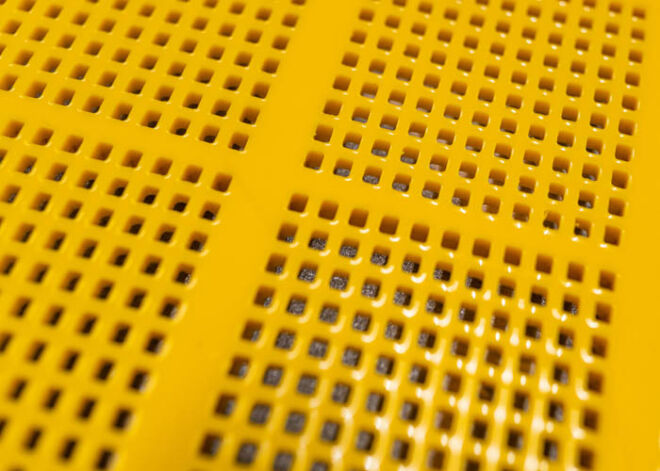

Polyurethane elastomer and abrasion-resistant rubber afford the highest protection against wear and tear. Polyurethane Screens made from these materials are longer lasting and reduce noise and are self-cleaning. Their modular layout and conical openings prevent the screen from clogging and they are very suitable for wet sorting and dewatering.

Features & Advantages

Corrosion Proof / Reduced wear and tear / Self-cleaning / Reduced noise / Reduced breakage.

Solutions for excellent screening performance

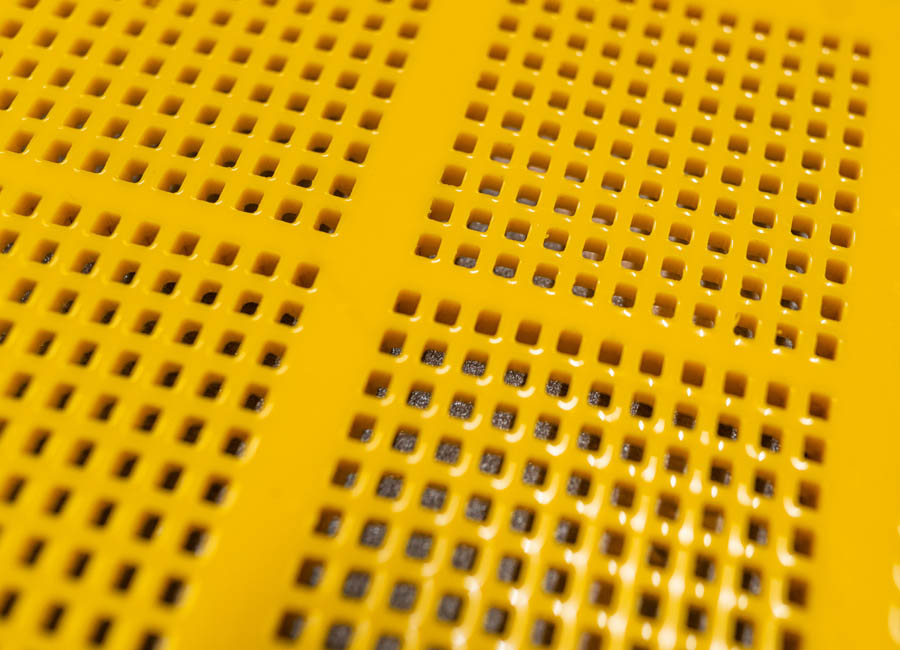

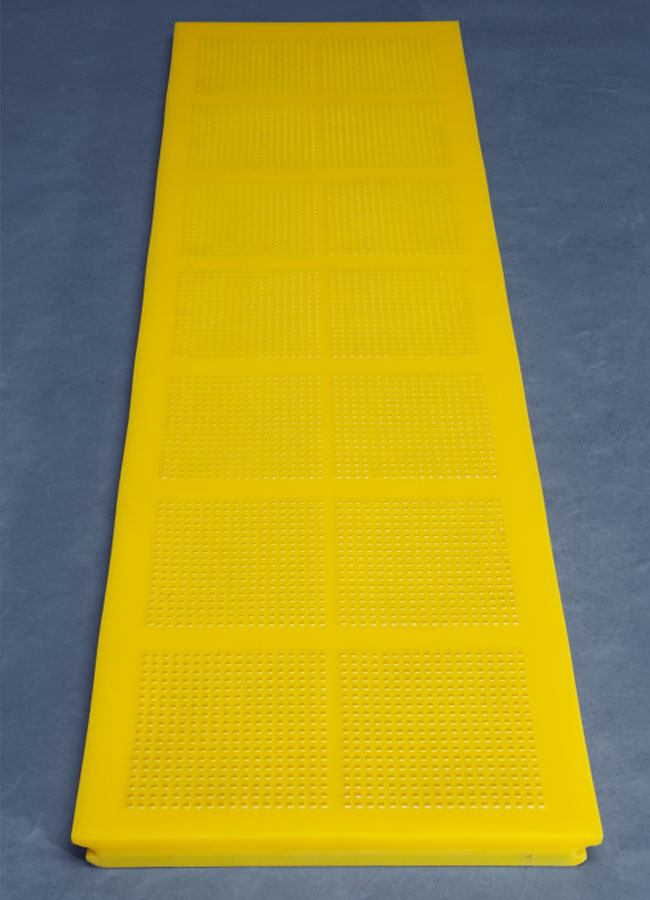

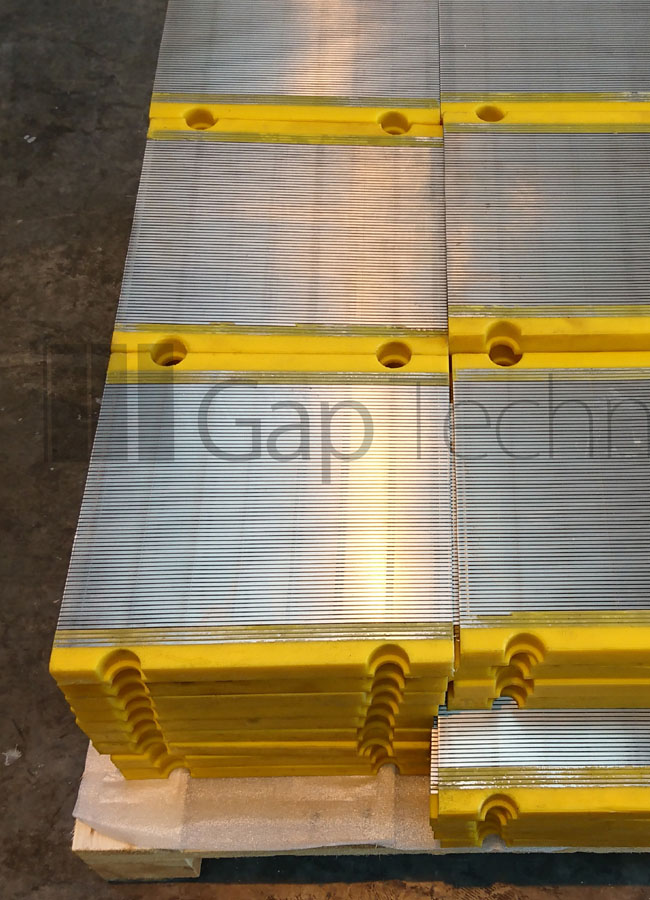

Modular Polyurethane Screens

With a high strength polyurethane coating and an extremely wear and tear resistant surface, the Polyurethane Screens are manufactured with reinforcement bars parallel to the panel width. Modular Screens are a cost effective modular system achieving optimal results mainly used in applications to separate Gravel, Quartzite, Sand, Gravel, Limestone and Coal just to name a few.

SOLUTIONS

Modular screens are the best solution for mining, sand and gravel screening, compost / wood chip processing and aggregate-ore processing as they offer a similar open area ratio of woven wire screens but the screens coating means that they last up to five times longer than steel meshes.

MORE

For more detailed information including strength and resistance tabular data visit our dedicated Modular Screens website page.

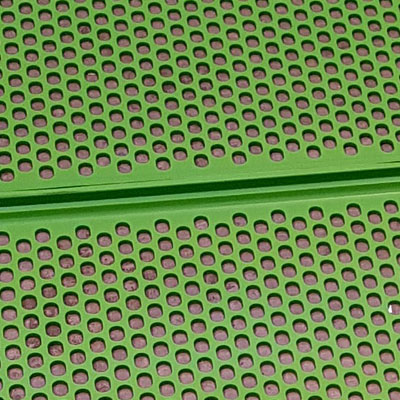

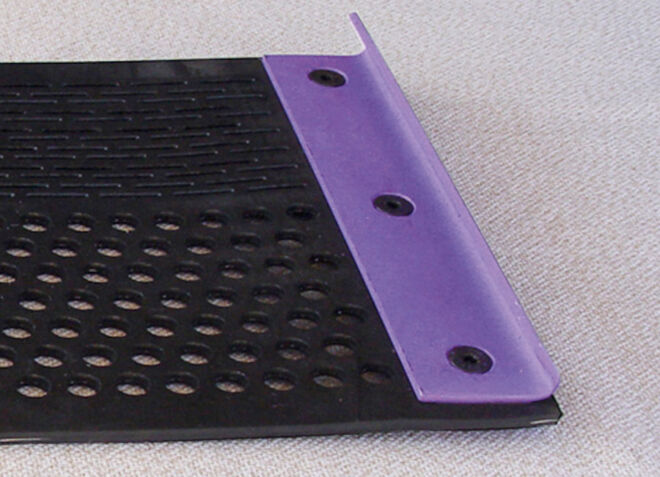

Tension Polyurethane Screens

Fitted to vibrating screens and these Polyurethane Tension Screens are an ideal cost effective alternative to metal with improved productivity used in the separation of aggregate both in the dry and wet conditions.

We are capable is manufacturing these Tension Screens to custom installations and can be configured to single or double crown, side tensioned, flat clamped or end tensioned.

OPTIONS

For coarse, medium & fine screening, Polyurethane Tensioned Screens are available in a wide range of apertures and shore hardness’s, providing a high wear and corrosive resistant screen media for a range of applications from scalping to dewatering.

MORE

For more detailed information including strength and resistance tabular data visit our dedicated Tension Screens website page.

Terminology

Polyurethane type screens are known by many variations in terminology, commonly these include:

- Polyurethane Mesh.

- Polyurethane Screening Panels.

- Polyurethane Screen Deck.

- Polyurethane Screen Mesh.

- Polyurethane Vibrating Screens.

MORE

For more information. why not visit our dedicated website at:

www.polyurethanescreens.co.uk

Photo gallery

Our industry standard cost effective, long lasting screens can be produced to fit individual requirements, equipment size and location. Ideally suited for the separation of Sand, Gravel, Granite, Quartzite, Limestone and Coal to name a few. Contact Gap Technology for support and enquiries.

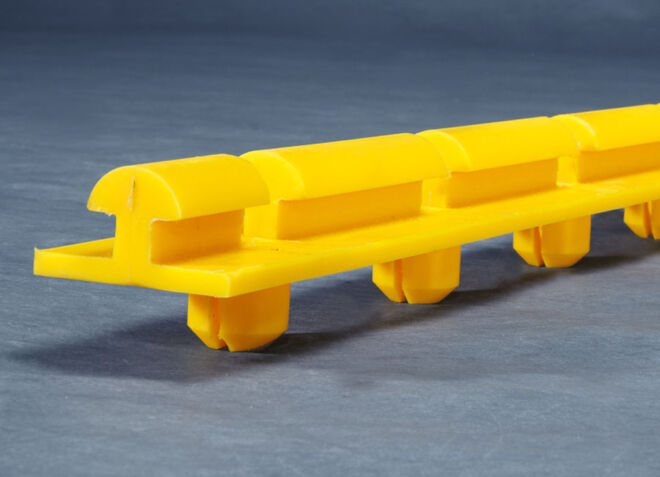

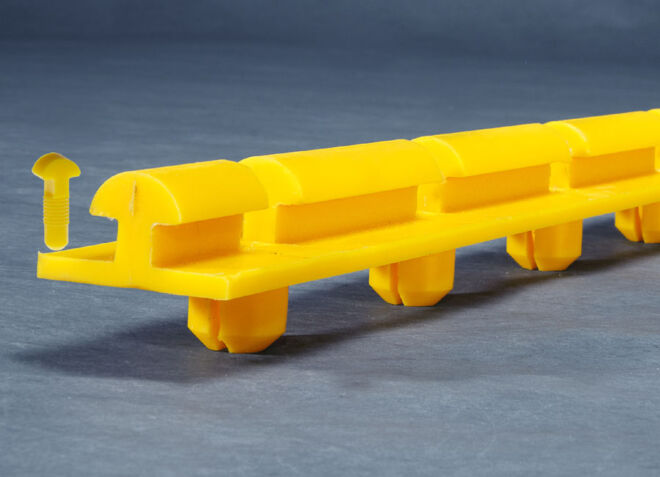

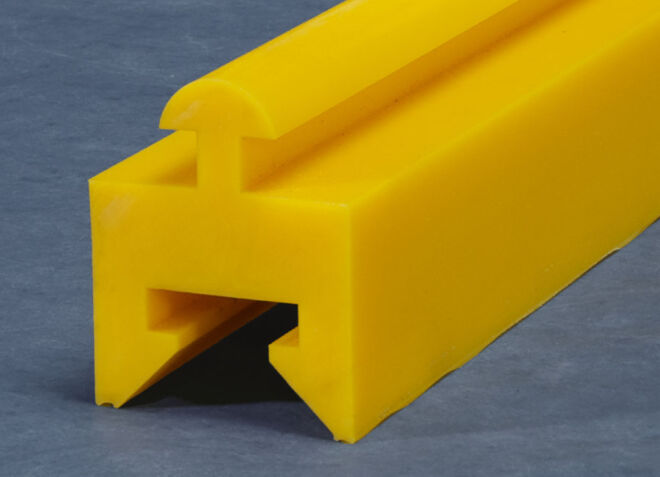

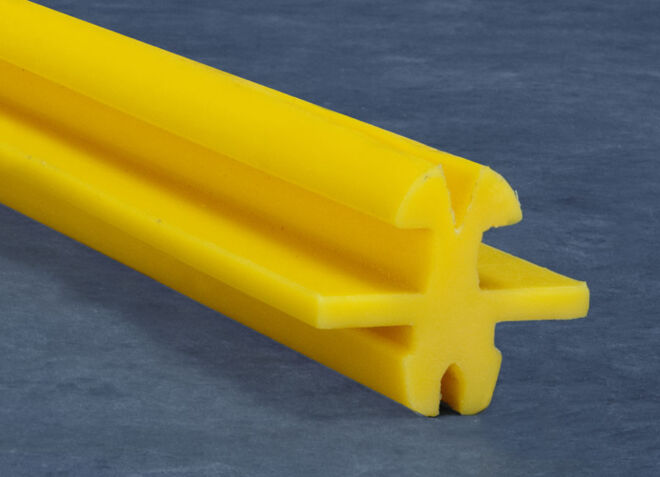

Polyurethane Screen Adapters & Accessories

Adaptors and Accessories for Modular and Tension Polyurethane Screens include: Standard Adapters / 7/9 Pin Adapter / Adapter with Support / Wall Fitted Adapter / T-Profile Adapter / Fixing Peg / Classic Sidebar/Sideliner with Wedge / Screwed Sidebar / Integrated Sidebar. Contact Gap Technology for support and enquiries.

Have a question?

If you would like to ask a question or have a enquiry regarding polyurethane modular or tensioned screens in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk