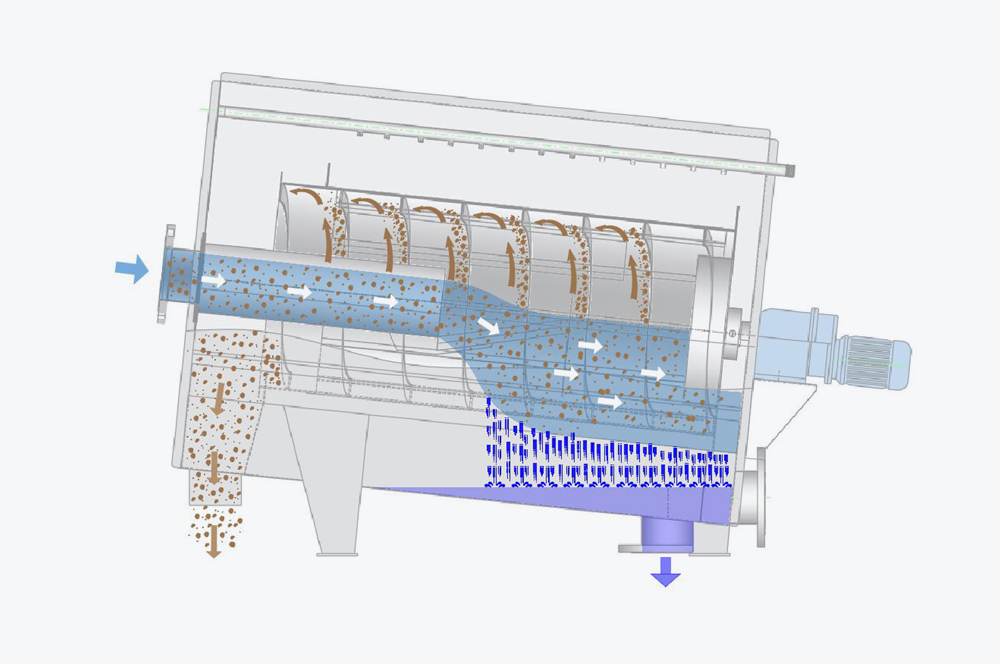

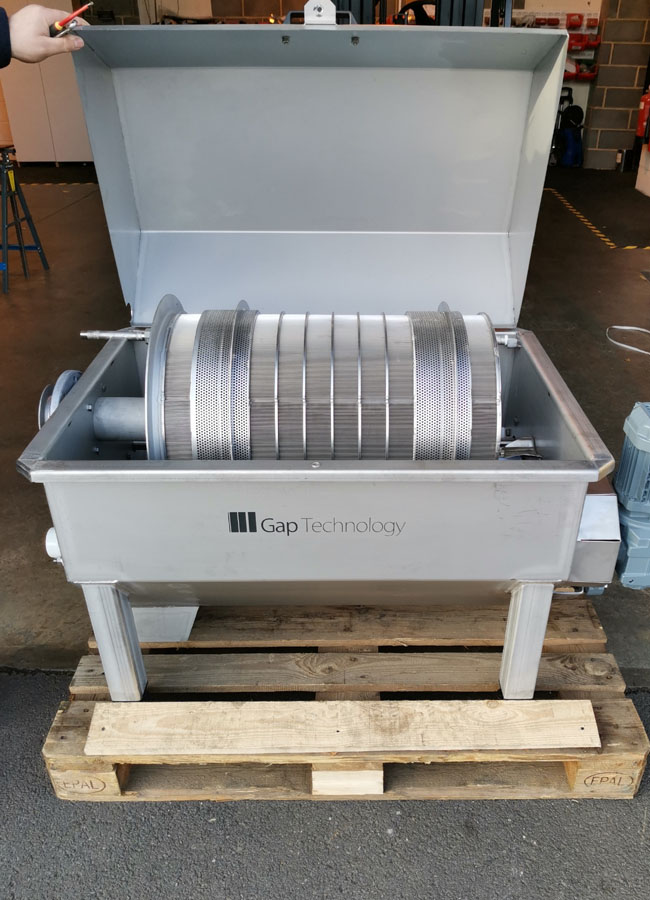

Fully enclosed & mechanically driven internal rotary screens with an integrated wash system

Introduction

Internal Rotary Drum Screens provide confined solids discharge and ideally suited for direct feeds into a compactor / compacting rotary screw system if further handling is required. Internal Rotary Screens can be installed as a stand alone system or as part of any treatment plant at the primary stage.

Internal Rotary Screens operate with an internal wedge wire construction, woven wire or perforated drum. Single or multiple rotary screen units are supplied for duty standby and duty assist situations.

Wedge Wire profiles and technical data.

Features & Benefits

- Inclined Drum design.

- Autonomous operation.

- Robust self contained technology.

- sprays and brushes.

- Confined solids discharge in numerous configurations.

- Ideal for direct feeds into a compactor.

- Stand alone system installations.

- Option to install as part of any treatment plant.

- Tailored to suit bespoke requirements.

- Supplied complete, with removable covers & safety switches.

- Isolator stop/start control panels.

- Incorporated overflow facilities with level sensors.

- Complete scroll.

- Overflow facility.

- Direct drive.

On-site Demonstrations

Internal Rotary Drum Screens on-site demonstration facilities are available along with the entire range of our Waste Water Screening Machines, each with interchangeable screen elements to determine the ideal separation of your materials.

Gap Technology Limited also provide structural steel work including platforms, handrailing and access ladders with a bespoke design, commissioning and installation service.

Interested in an on-site demonstration?

Contact Gap Technology

Technical Information & Specifications

| Types | Modular |

| Media: Liquids | Grey Water, Industrial Effluents, Process Water, Sewage & Storm Water |

| Media: Solids | TSS Reduction, Industrial and Municipal Process Screenings |

| Screen Types | Drums screens, Inlet screens and Rotating screens |

| Materials | Stainless Steel, Stainless Steel (304) and Stainless Steel (316) |

| Features | Self cleaning |

| Maximum aperture size (mm) | 6 |

| Minimum aperture size | 0.25 |

INCLINED DRUM Flow Capabilities (m3/hour)

Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| MODEL | SLOT GAP (mm) | Unladen weights | |||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.40 | 3.00 | Nominal | |

| IRS 6250 | 38 | 47 | 54 | 92 | 108 | 260 | 350 kgs |

| IRS 9200 | 79 | 110 | 150 | 211 | 324 | 650 | 950 kgs |

| IRS 1230 | 136 | 255 | 398 | 643 | 1045 | 2200 | 1300 kgs |

IRS 600 INCLINED DRUM Flow Capabilities (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| Type IRS | SLOT / GAP s (mm) | |||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | 2.00 | |

| IRS 600 x 1270 | 50 | 105 | 140 | 170 | 200 | 225 |

| IRS 600 x 1570 | 65 | 125 | 165 | 205 | 240 | 260 |

IRS 900 INCLINED DRUM Flow Capabilities (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| Type | SLOT / GAP s (mm) | |||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | 2.00 | |

| IRS 900 x 1500 | 120 | 220 | 310 | 380 | 490 | 570 |

| IRS 900 x 2000 | 160 | 300 | 410 | 520 | 670 | 770 |

| IRS 900 x 2400 | 190 | 360 | 490 | 620 | 790 | 910 |

IRS 1200 x 3000 INCLINED DRUM Flow Capabilities (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| Type | SLOT / GAP s (mm) | |||||

| 0.75mm | 1.0mm | 3.0mm | ||||

| IRS 1230 | 700 | 1045 | 2200 | |||

Photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding waste water screening machines in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk