Abattoir in Mecca, Saudia Arabia

DAF sludge waste from an abattoir processing plant

Dissolved air flotation or DAF sludge dewatering and filtering systems are used in a variety of industries and applications to remove suspended solids, fats, oils and greases from a variety of wastewaters. Red meat processing results in the production of a range of solid wastes. Disposal of solid waste is often related with high costs, which gives abattoirs an incentive to reduce solid waste production.

In the first instance, within the processing of sludge waste it is necessary to reduce the sludge volumes produced within the course of the wastewater treatment process. This is achieved by the separation of sludge at different points within the sludge treatment process chain.

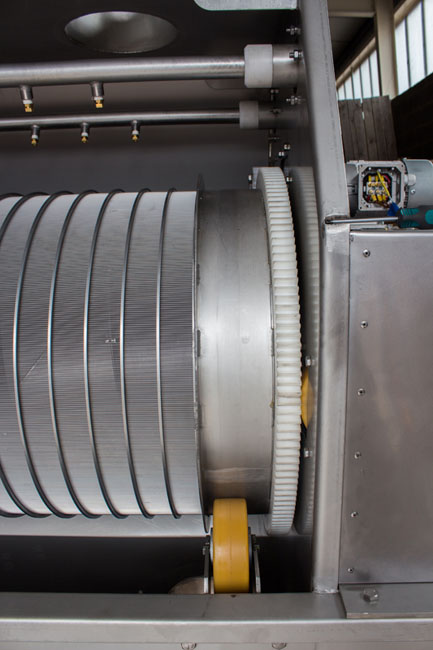

Primarily the GST-6-157 sludge thickener with a 0.50mm slot / aperture was supplied for the purpose of reducing the volume of the sludge prior to stabilisation.

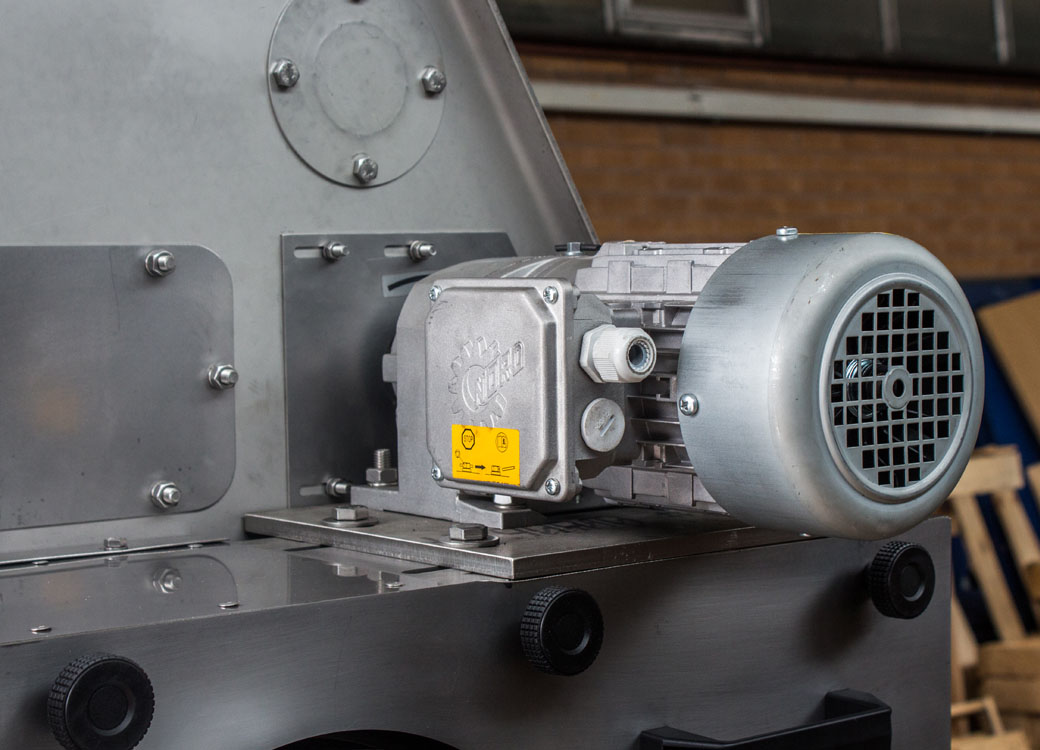

The Conveying Compactor was designed and manufactured to take the sludge from the machine to the outside waste bin. Gap Technology supply precision compactors / rotating screw system, conveying solids through a highly efficient wedge wire filter chamber.

The Floc tank with slow speed drive unit and paddle mixer was ideal for the storage of waste with an open top to allow operators to observe floc conditions and levels.

Due to temperatures in Saudi Arabia, a bespoke 40ft container was designed and manufactured to house the machines on site, with a bespoke air conditioning unit to keep the machinery cool in the hot weather.

MORE

Contact Gap Technology

for more information, support and enquiries.

Gap Technology Limited

Head Office & Works

Ava House, 1 Hill Court

Aurillac Way

Retford

Nottinghamshire

DN22 7PX

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk