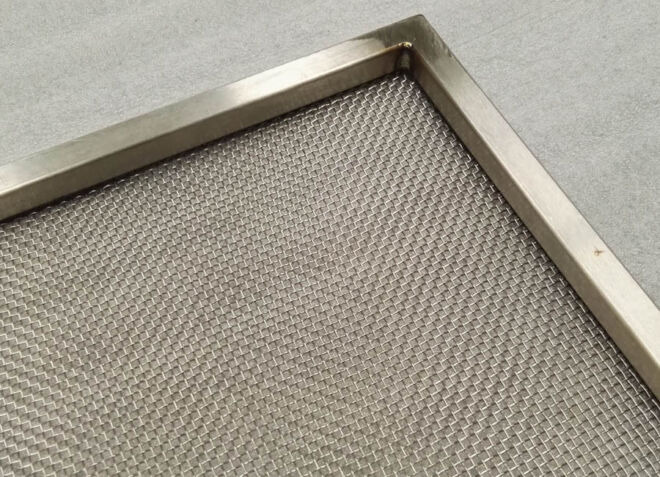

Sieves, Filters & Mesh for industrial applications

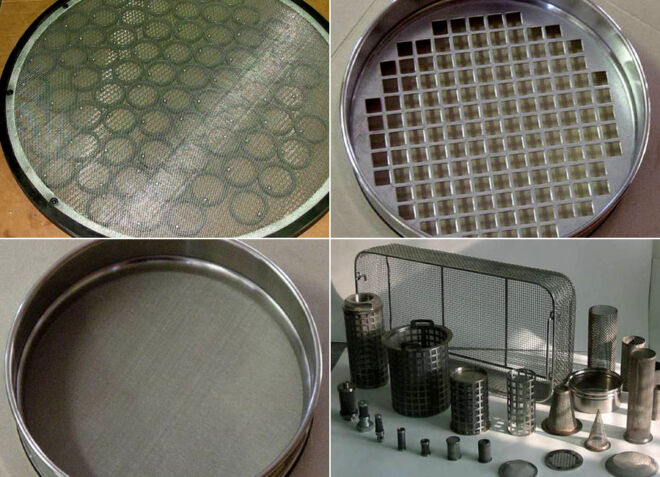

Our Sieves and Filters / Meshes are produced in accordance with the customers drawing or product sample supplied. Our Sieves and Filters / Mesh products are mainly used in the chemical, engineering or food industry to name but a few.

Our standard range of wire cloths are sold in rolls or can be supplied by the metre with a production width of 1000mm and our bespoke range with the width ranging from 2500-3009mm. Our laboratory sieves and filter products are focused on machines and devices used for sieve analysis of particle sizes and related processes. Upon receipt of an enquiry, we will evaluate the customers requirements to determine what equipment is needed.

Weave arrangements for sieves, filters & mesh

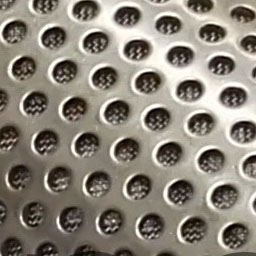

Our Square Mesh, Rectangular Mesh and Zero Mesh arrangements are used in a variety of applications from sieves and filters, screens, sorters, conveyor belts, protective equipment, reinforcements, supports to name only a few, using the two industry standard methods; Warp, wires placed in the lengthways direction and Weft, wires placed transversely. Contact Gap Technology for support and enquiries.

Smooth Weave

This is the most common method of production. Every wire is bent either in the warp or in the weft and this alternates regularly.

Twilled Weave

Two wires are always bent with a subsequent offset over one wire. This weave is chosen mainly in cases when the wire is too thick with respect to the mesh size or if the cloth is too fine and therefore the bent wire does not stay in the woven weaves.

Alternate Twilled Weave Sieves

This weaving method is used when it is necessary to eliminate possible crosswise displacements. Because of frequent hole differences it is mainly used for various inserts and only very rarely for filters and screens.

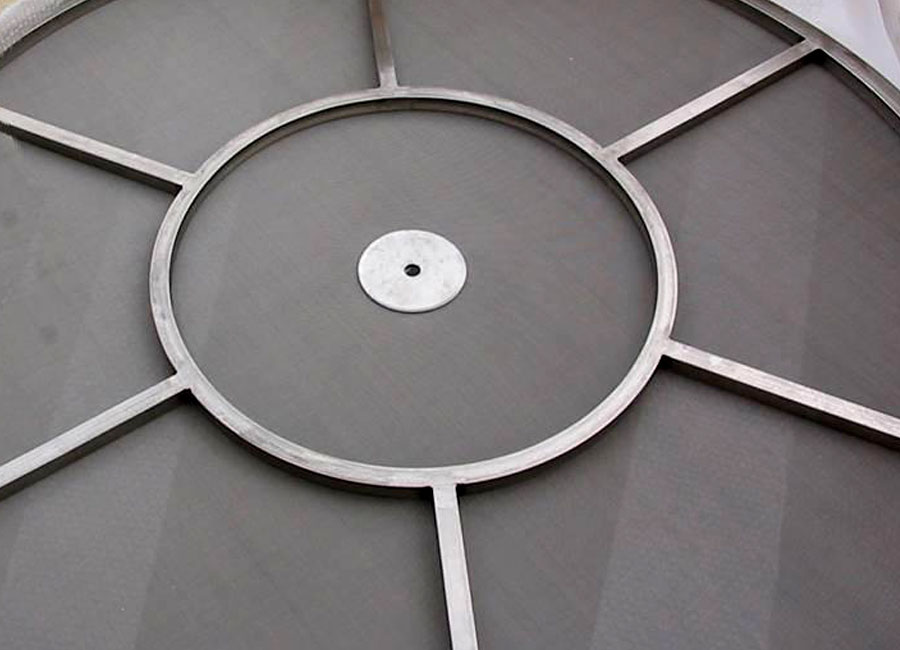

Sieves photo gallery

Cloth Filter types and arrangements

The types of cloth produced will depend on the arrangement of the weave; repeating alteration of warp and weft wires in lengthways and transverse direction of the cloth.

Contact Gap Technology for support and enquiries.

Smooth Weave

The weft wires are tightly close one to another, that “zero meshes” are created. Warp wires are thicker than weft wires. The good flow capacity determined by the identical holes and also easy cleaning are the main positive features.

Twilled Weave

The weft wires are placed closely next to one another in the twilled weave. One weft wire always lays above and one below the warp wire. The number of wires is doubled compared to the woven weave.

Armoured Filter Inverted Belt

Unlike woven weave belts most wires are in the warp system. Therefore the weft wires are considerably thicker than the warp wires. This special construction produces great stability and it ensures good flow capacity.

Broad Mesh

This filter cloth is produced in the same way as the common belts. Weft wires are not laid so closely next to each other but at a certain distance and this increases flow capacity. The disadvantage is a low degree of hole regularity. Broad filter cloth is produced in both Smooth & Twilled Weave.

Armoured Twilled

It is a technical cloth where the combination of the twilled weave and the location of most of the wires in the warp creates high stability and strength, allowing the use in extremely demanding environments.

Have a question?

If you would like to ask a question or have a enquiry regarding Sieves, Filters & Mesh or Technical Cloth in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk