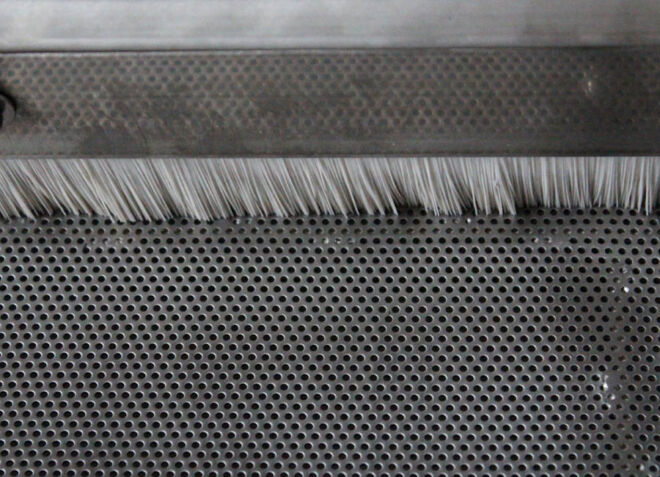

Brush Screens – brush, rubber or plastic blade arrangements for the consistent removal of dewatered solids

Introduction

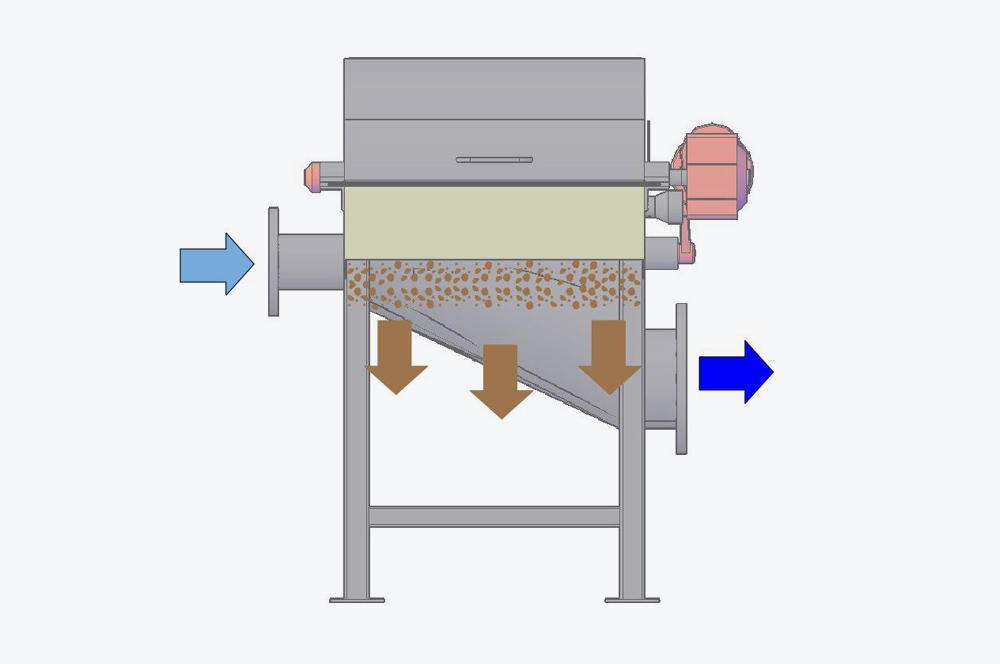

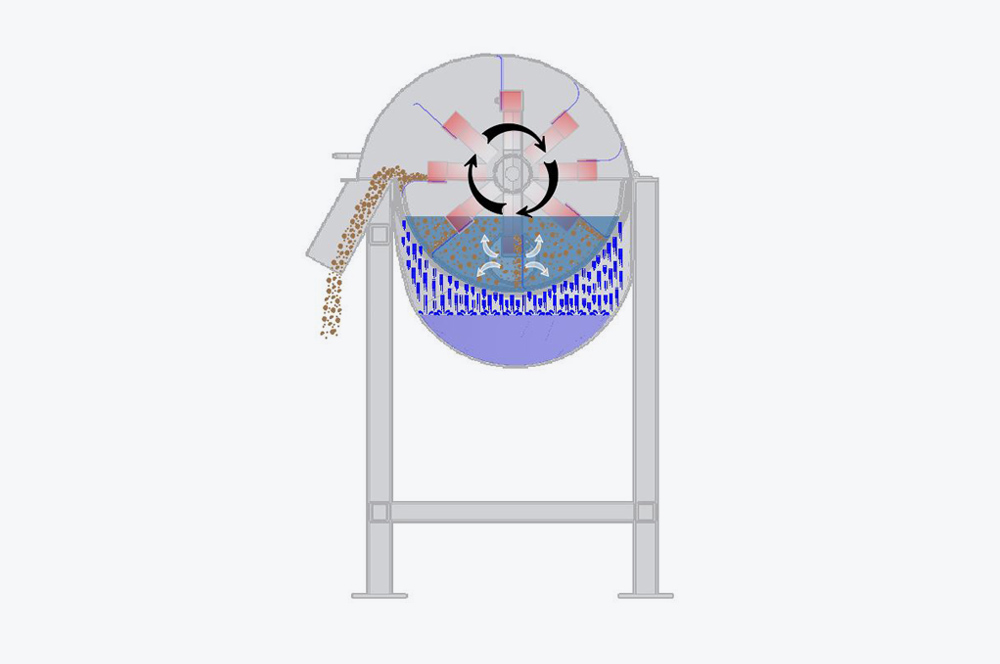

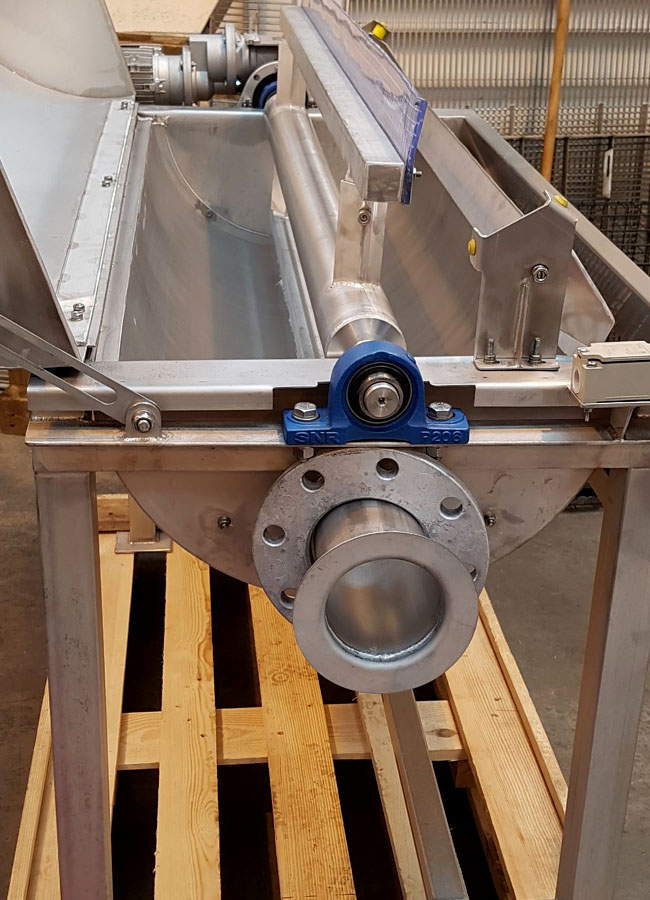

Brush Screens otherwise known as Brush Rotary Screens (BRS) are mechanically driven brush screens system with a multi paddle rotating axle.

These Brush Screens can incorporate a brush, rubber or plastic blade arrangement for the consistent removal of dewatered solids from the wedge wire or perforated plate screen surface. Our Brush Screens are the ideal choice.

Brush Screens are available in a range of sizes to accommodate most industrial or municipal applications.

Wedge Wire profiles and technical data.

Features & Benefits

- Mechanically driven brush rotary screen system.

- Multi paddle rotating axle.

- Brush, rubber or plastic blade arrangements.

- Consistent removal of surface dewatered solids.

- Range of sizes to accommodate most industrial or municipal applications.

On-site Demonstrations

Brush Screens / Brush Rotary Screens (BRS) on-site demonstration facilities are available along with the entire range of our Waste Water Screening Machines, each with interchangeable screen elements to determine the ideal separation of your materials.

Gap Technology Limited also provide structural steel work including platforms, handrailing and access ladders with a bespoke design, commissioning and installation service.

Interested in an on-site demonstration?

Contact Gap Technology

Technical Information & Specifications

| Media: Liquids | Grey Water, Industrial Effluents, Process Water, Sewage & Storm Water |

| Media: Solids | TSS Reduction, Industrial and Municipal Process Screenings |

| Screen Types | Wedge Wire or Perforated D-Screen with Rotating Brush Wiper |

| Materials | Stainless Steel, Stainless Steel (304) and Stainless Steel (316) |

| Features | No Wash Water Facility |

| Maximum aperture size (mm) | 3 |

| Minimum aperture size | 0.25 |

FLOW CAPABILITIES (per screen width)

Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| SLOT GAP (mm) | BRS 500 | BRS 1000 | BRS 1250 | BRS 2000 | ||||

| gpm / ft | m3 / hr / m | gpm / ft | m3 / hr / m | gpm / ft | m3 / hr / m | gpm / ft | m3 / hr / m | |

| 0.25 | 6.0 | 5.50 | 10.25 | 9.50 | 12.0 | 11.25 | 15.50 | 14.20 |

| 0.50 | 11.0 | 10.0 | 18.25 | 16.50 | 25.0 | 22.50 | 31.25 | 28.5 |

| 3.00 | 78.0 | 72.0 | 130.0 | 120.0 | 166.0 | 153.0 | 206.0 | 192.0 |

Photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding waste water screening machines in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk