Rotary drum, and trommel screens are essential pieces of equipment in the material processing industry. They are used to separate and classify different types of materials based on their size, shape, and density. These screens have revolutionized the way materials are handled, making the process more efficient and cost-effective.

Rotary Screens

Rotary screens, also known as rotary sieves, are cylindrical screens that rotate at a constant speed. They are used for dewatering applications and to separate large and small particles by size. The material is fed into the screen at one end, and as it rotates, the smaller particles pass through the holes in the screen, while the larger particles are retained and continue to move along the screen.

This process is repeated until all the material has been separated into different sizes. Rotary screens are commonly used in industries such as agriculture, mining, and waste management.

Example uses

- Industrial Process Waste Water Treatment.

- Food & Beverage.

- Agriculture.

- Quarrying and Recycling.

- Mining.

- Waste Management.

Drum Screens

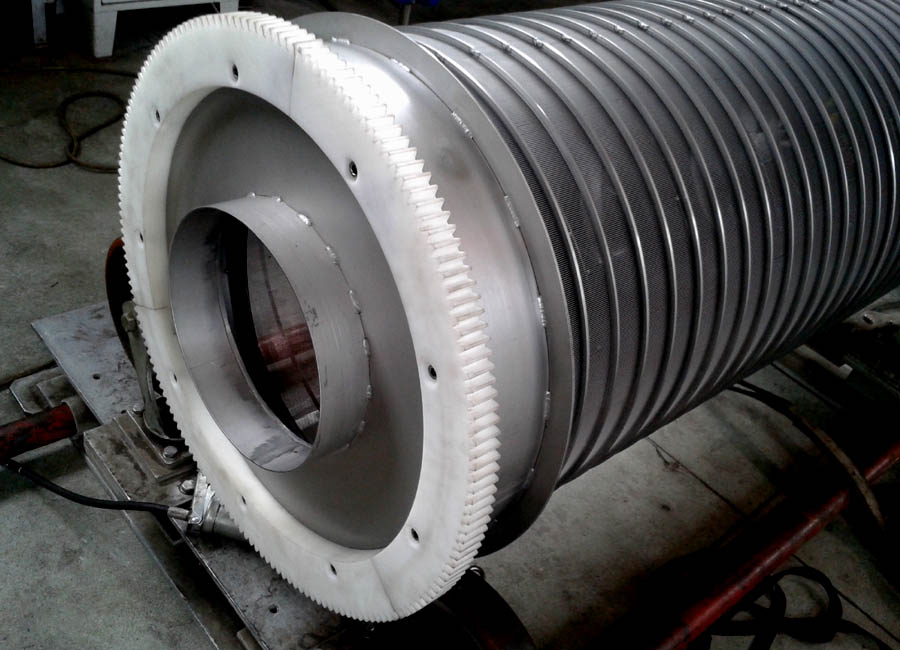

Drum screens, also known as drum sieves, are similar to rotary screens in that they also rotate to separate materials by size. However, drum screens have a cylindrical shape with a mesh or perforated surface that allows smaller particles to pass through while retaining larger particles.

They are commonly used in industries such as food processing, chemical, and wastewater treatment. Drum screens are versatile and can be used for various applications, including solid-liquid separation, product recovery, and waste management.

Example uses

- Solid-liquid separation.

- Product recovery.

- Waste Management.

Trommel Screens

Trommel screens, also known as trommel sieves, are cylindrical screens with a rotating drum that is inclined at an angle. The material is fed into the top of the drum, and as it rotates, the smaller particles fall through the holes in the screen, while the larger particles are retained and continue to move along the screen.

Trommel screens are commonly used in the mining industry to separate valuable minerals from waste materials. They are also used in composting, wood processing, and other recycling applications – such as in the sugar industry for the separation of raw sugar juice from the crop (Bagass).

Example uses

- Mining.

- Composting.

- Wood processing.

- Recycling applications.

- Sugar / Food Processing.

Advantages and versatility for a wide range of applications.

- Ability to handle a large volume of material.

- Process materials at a high rate, ideal for industries that require fast & efficient screening.

- Compact design, which saves space and allows for easy installation.

- Low maintenance, with minimal moving parts, making them cost-effective and reliable.

Environmental benefits, efficiency and sustainability.

By separating materials based on their size and density, these rotary trommel screens can help reduce waste and increase the recycling rate. They also help to reduce the amount of material that goes into landfills, contributing to a cleaner and healthier environment.

In conclusion, they are essential pieces of equipment in the material processing industry. They offer high efficiency, versatility, and environmental benefits, making them a valuable asset for various industries. With advancements in technology, these screens continue to evolve and improve, making the material handling process more efficient and sustainable.

Have a question?

If you would like to ask a question or have a enquiry regarding Rotary Drum and Trommel Screens in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk